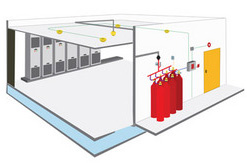

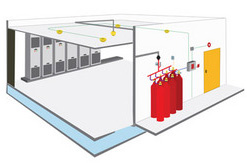

Constructing a Clean Agent Room

The following work is traditionally provided by other trades and is not included in the scope of work

of the clean agent fire suppression systems contractor.

Integrity Room Systems: Doors & Windows

- 1. Ensure threshold and sweep are installed on all doors.

- 2. Verify that all Egress doors swing out of the protected area.

- 3. Check doors to determine if they require weather stripping around the jam to ensure an air tight seal.

- 4. Latching mechanisms are a necessity. Door closures may also be needed.

- 5. In the event that doors need to be opened, use of an electromagnet door holder will be necessary and released prior to agent discharge.

- 6. All areas such as, windows, pass throughs, or any type of opening, are fire caulked and sealed.

Integrity Room Systems: Walls, Ceiling, & Floors

- 1. Seal porous block walls from slab to slab prevents gas from passing through. Two or three coats of paint are typically applied.

- 2. Wall partitions which extend slab-to-slab are used to enclose protected areas. If this is not possible, ceiling tiles should be clipped and all openings caulked.

- 3. Walls are caulked around the inside border of the room where walls rest on the floor slabs and walls intersect with ceiling slab above.

- 4. We recommend upgrading the ceiling tiles.

- 5. Caulking of the drywall at joints of the walls, floors, roof or floor above.

- 6. All conduit, cable trays, outlets, switches and wire troughs are fire caulked and sealed.

- 7. In the event that a raised floor continues outside the protected area, bulkheads are installed under the floor directly under the partitions. We then caulk the top and bottom of these bulkheads.

- 8. We ensure that all floor drains have traps and that the traps are designed to have water in them at all times.

Mechanical Contractor: HVAC Specialties

- 1. Dampers may be required in the ductwork at the perimeter walls of each protected area. This ensures the protected area is air tight.

- NOTE: Dampers may also be required to provide pressure relief vent area for applications using Clean Agent Fire Extinguishing Systems. IRS

uses the FSSA pressure relief vent area calculation software to assist you in determining what if any vent relief is required.

This method, when used in conjunction with a site specific door fan test will determine the most efficient damper size for the enclosure.

- 2. In order to provide 100% air shut off, dampers must be spring loaded or motor operated.

- 3. In order to meet the minimum leakage requirements, all dampers are to be UL #5555.

- 4. Prior to discharging the agent, all HVAC in the protected area may be required to be shutdown.

If HVAC is self-contained protected by clean agent in all spaces including plenums and approved by the AHJ, they may continue to run.

- 5. Installed HVAC shut down control relays should be within 3 ft. of each unit.

- 6. It is recommended that all exhaust fans be dampered. In order to shutdown any fans, fire alarm system control relays are used.

- 7. All fresh air intakes shall be dampered and closed.

Electrical Contractor: Power and Interface Wiring

- 1. It is required that there be a 120 VAC dedicated 15 AMP circuit to the suppression control panel.

- 2. There should be power to all dampers within 3 ft. of damper.

- 3. Fire alarm monitoring - contacts for alarm, supervisory and trouble conditions are available within the fire control panel. Connection is handled by fire system contractor.

- 4. Purge system control wiring to HVAC units and exhaust fans are interfaced with the fire alarm system control panel. Connection is handled by the fire system contractor.

Download Clean Agent Room Info